Development Opportunity

Request for shorter curing time for thermosetting resin products

In recent years, cost reduction through productivity improvement has become more and more important in order to strengthen competitiveness.

We have received many requests for shorter curing times for our thermosetting resin products.

For example, general thermosetting epoxy resins require at least several tens of minutes to cure, but what customers actually require is a level of several tens of seconds to several minutes.

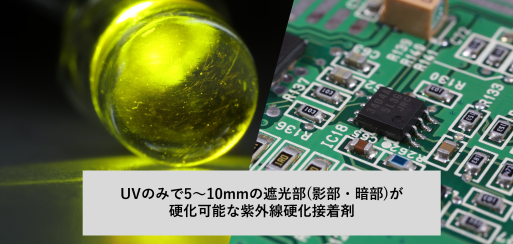

For this reason, we have focused on UV curing and decided to develop UV curable adhesives that can be cured in tens of seconds.

TASK

Is it possible to cure areas that light cannot reach using only UV irradiation?

In developing UV curable adhesives, we focused on one issue.

That is, “Is it possible to cure even the areas where UV light does not reach (shadowed or shaded areas) just by UV irradiation?

This was the challenge we faced.

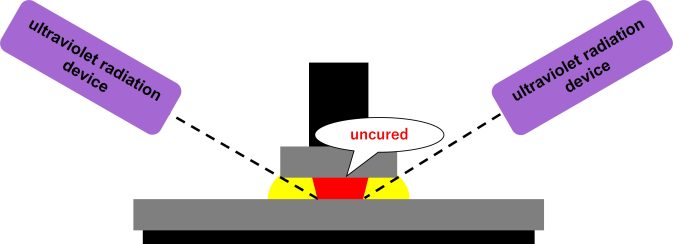

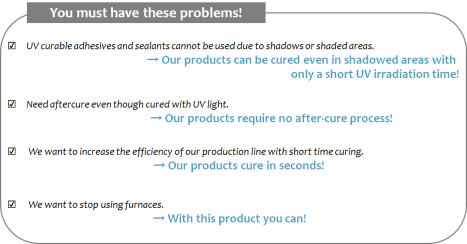

Specifically, with general UV curable materials, as shown in the figure, the reaction does not progress in areas where UV light does not reach, and therefore, the material does not cure.

For this reason, dual curing, which combines heat curing or moisture curing, is often used when there are shadowed or shaded areas.

However, dual curing has the following problems…

- Additional heating process is required for thermosetting, and it cannot be used for heat-sensitive materials.

- When moisture curing is used, curing time is long and may take nearly a week.

Therefore, we decided to form a project team to study the solution to this issue.

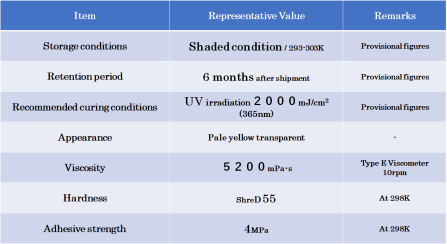

Introduction of Developed Product

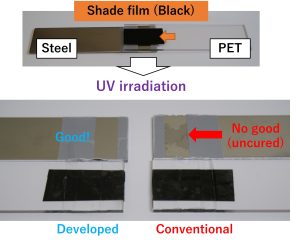

As a result of the project team’s study, test results showed that curing is possible with UV irradiation alone, even in the presence of approximately 5 to 10 mm of light shading (shadow or dark areas) (see the figure below).

We are planning to study the improvement of the adhesion and various reliability tests for practical use in the future.

Examples of Uses

- Bonding of enclosures, boss parts, etc.

- Sealing and molding related to electronic components

- Fixing of coil ends

- Bonding of O-rings for various seals, film con

- Optical applications such as OCR

Author: Mr. Yasunaga, Development 1 Group; Mr. Watanabe, IV Strategy Unit

Inquiries about developed products

If you have a sample request, please fill out the contact form.

A representative will contact you shortly.