The endless struggle between electronic components and heat

Heat is the natural enemy of electronic components.

The higher the temperature during operation, the majority of electronic equipments perform poorly, become unstable, deteriorate and have a shorter life time.

The path taken by electronic devices is a one-way street of higher performance.

Increasing performance tends to increase power consumption.

And there are getting smaller and smaller.

Electronic devices are heating up year after year as large amounts of power, into a small space.

In the past and in the future, electronic components struggle with heat.

There is no end in sight.

So what should we do?

General thermal countermeasures are as follows.

Attach heat-dissipating fins or small fans to cool electronic devices by directing air to them.

Reduce heat generation by devising the structure of the electronic components themselves, which are heat sources, and the design of electronic circuits.

In particular, “cooling” is a quick and effective method.

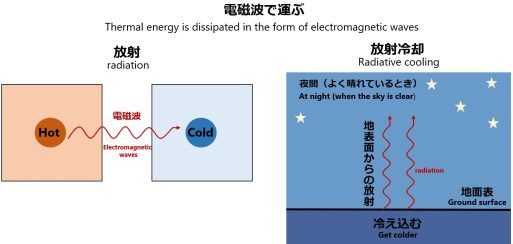

“Cooling” means to transfer heat(energy) from a hot place to a cold place.

This can only be realized by transport by the movement of electrons, atoms, and molecules (thermal conduction and convection) or by electromagnetic waves (thermal radiation).

What is the critical difference between these cooling methods?

In thermal conduction and convection, heat is transported when a hot state is in direct contact with a cold state, whereas in thermal radiation, it is transported to a place that is not in direct contact.

Can you imagine “carrying heat in electromagnetic waves?”

It is happening very close to home.

For example, on a clear and dry winter morning, frost columns form on the ground even when the outside temperature is not below freezing.

This is a phenomenon in which heat on the ground becomes electromagnetic waves that are carried to cold outer space during the night, cooling the ground.

The effect of “Thermal Radiation Cooling” is quite great.

In the desert, a temperature drop of 40℃ relative to the outside temperature is thought to be possible.

If the effect of “Thermal Radiation Cooling” is used properly, it is possible to save energy by lowering the temperature in daylight.

What is PelcoolⓇ H-7020?

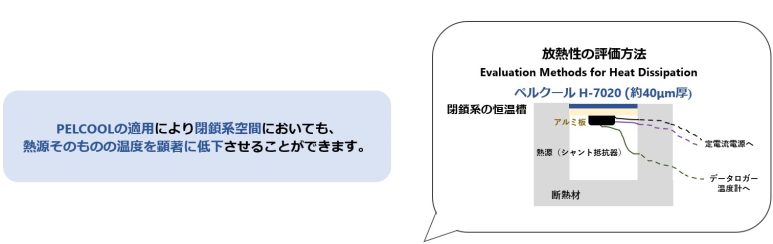

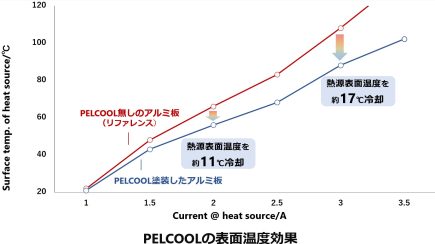

PelcoolⓇ H-7020 is a paint that takes full advantage of this mechanism of cooling by “Thermal Radiation”.

This paint is easy to handle because it is composed of inorganic particles responsible for thermal radiation cooling and resin components responsible for workability.

Simply painting with a sprayer or coater is effective.

The coating thickness is at most a few tens of micrometers thickness.

The coating is resistant to heat, solvents, acids, and alkalis, as well as synthetic and mineral oils, and have excellent resistance of weather, high temperature / high humidity environments and heat cycles.

One advantage of carrying heat in electromagnetic waves is that the cooling capacity is not reduced even if the surface is contaminated with mud and dust.

We can help you with the following thermal needs !

✓Need to lower the temperature as much as possible in the relatively low temperature range of 50-120 ℃, which is problematic for electronic components!

✓Need to obtain high cooling effect in a narrow space or closed system where cooling fins or cooling fans cannot be used!

✓Need to cool effectively a localized area where temperatures are high!

✓Want to reduce thermal management components!

Want to simplify product design and reduce component costs!

✓Want to reduce the temperature of equipment that serves as a heat source!

And don’t want the ambient temperature to be too high!

✓Don’t want to spend a lot of time on maintenance while take care of thermal management!

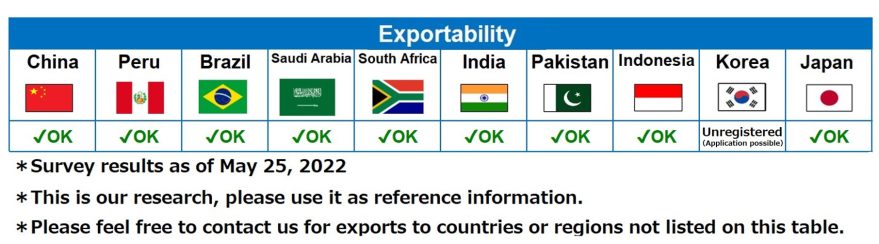

inventory information

As one of the solutions for thermal management

PelcoolⓇ has been recognized for its cooling effect in the following applications and is used in a variety of scenes.

・General LED lamps and commercial lighting fixtures

・Fish-luring lights

・Street lights

・Large lighting fixtures used in parking lots and construction sites

・Backlights for flat display

・Board enclosure for wireless base stations

・Solar cell

・Large motors

・Audio equipment, etc

Of course, it can be assembled into the conventional thermal management through heat conduction or convection.

Furthermore, PelcoolⓇ does more than just make coated parts highly thermal radiaction, but we also gives the paint with optimal heat dissipation performance according to the temperature the customer wants to cool down through patented material design technology.

It is also available in a wide variety of colors and is recommended for fashionable products with an emphasis on design.

We provide high-performance thermal management products with high heat resistance, high thermal conductivity, and flexibility.

We hope that Thermal radiation paint “PelcoolⓇ H-7020” introduced here will help you solve your thermal problems as one of our distinctive products.

developer of the H-7020

Inquiry about PelcoolⓇ H-7020

If you have a sample request, please fill out the contact form. A representative will contact you shortly.