Heat dissipation gap filler

What is heat dissipation gap filler?

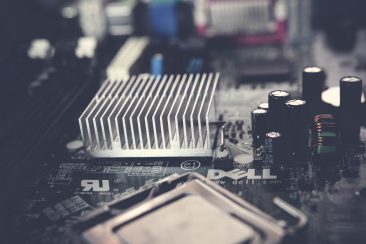

A heat-conductive resin material that is attached between components to efficiently exhaust heat generated inside equipment via a heat sink.

This is a paste-like liquid that hardens in a curing reaction and can harden in the targeted location and in the targeted thinness.

These are extremely effective when used in power supply units,

communication modules, LED lighting, automotive electrical components, lithium-ion batteries, power modules,

When used on parts that require thermal countermeasures, it can have a tremendous effect.

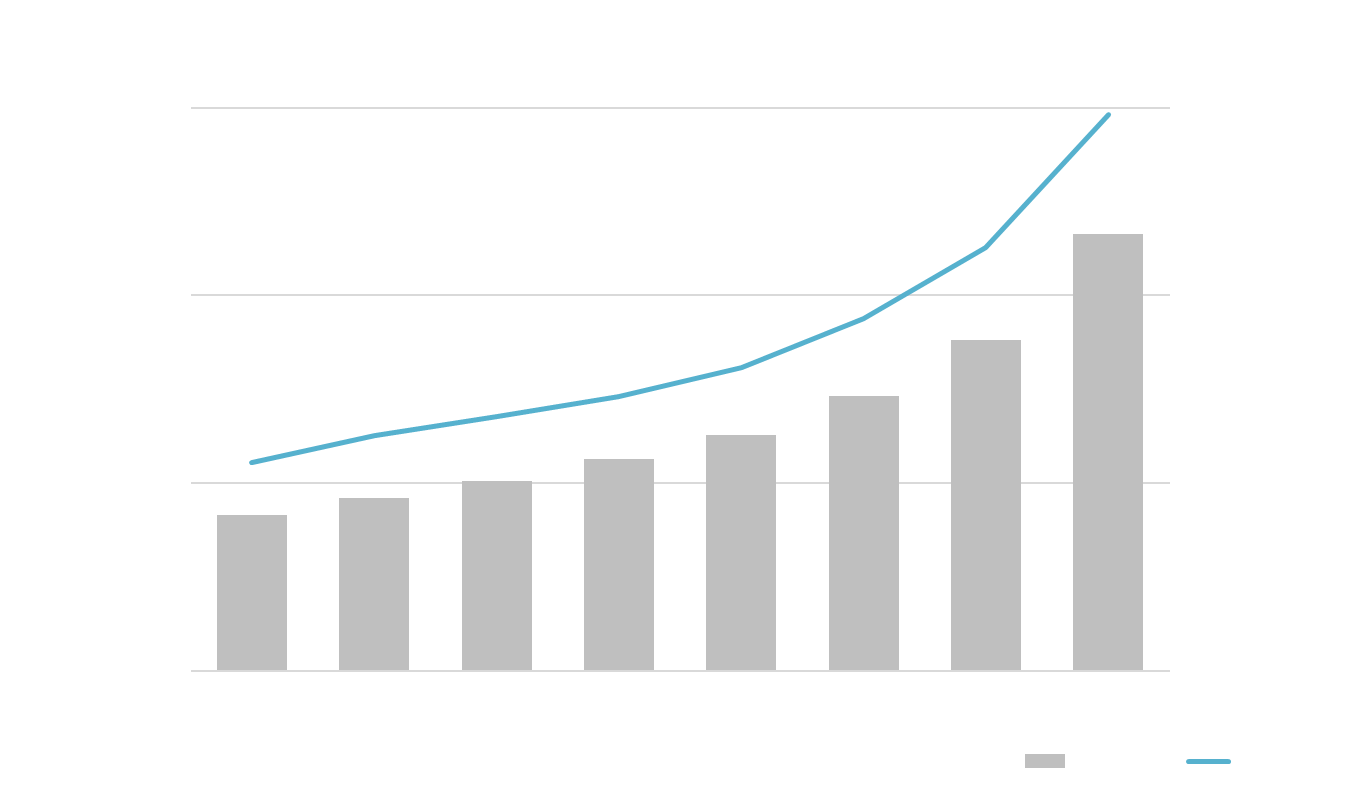

Growing gap filler market

The rapid increase in demand for electronic devices and LEDs, coupled with the miniaturization of components, requires thermal countermeasures to efficiently exhaust the heat generated inside devices.

As one approach to this, demand for thermally conductive resins inserted between components has expanded significantly.

Among them, “heat dissipation gap filler” is increasingly being applied in place of conventional “heat dissipation sheet” and “heat dissipation grease,” and its sales volume is expected to increase by about 30% in 2023 compared to the previous year.

In particular, the majority of the products are for automotive applications, and demand is growing due to the expansion of demand for HVs and EVs and the tailwind from the progress of in-vehicle electrification.

What characteristics are needed?

Thermal conductivity

High thermal conductivity suppresses heat storage.

It has the effect of increasing the heat removal effect.

Flexibility and Adhesion

It is flexible and adheres to any part shape.

The strong adhesion between the component and the heat-dissipating gap filler results in low thermal resistance at the adhesive interface, enabling efficient heat dissipation.

Pump-out and Dry-out resistance

It is not easily deformed or altered by heat or vibration, and can maintain the same characteristics for a long period of time.

Evolving

new heat dissipation gap filler

The mainstream heat dissipation gap filler is a material that uses silicone-based resin. However, silicone resins have various problems such as oil bleed and low molecular weight siloxane generation, which cause poor heat dissipation, short circuits, and contact failure.

To solve this problem, we are developing a new heat dissipation gap filler using a thermosetting type urethane resin!

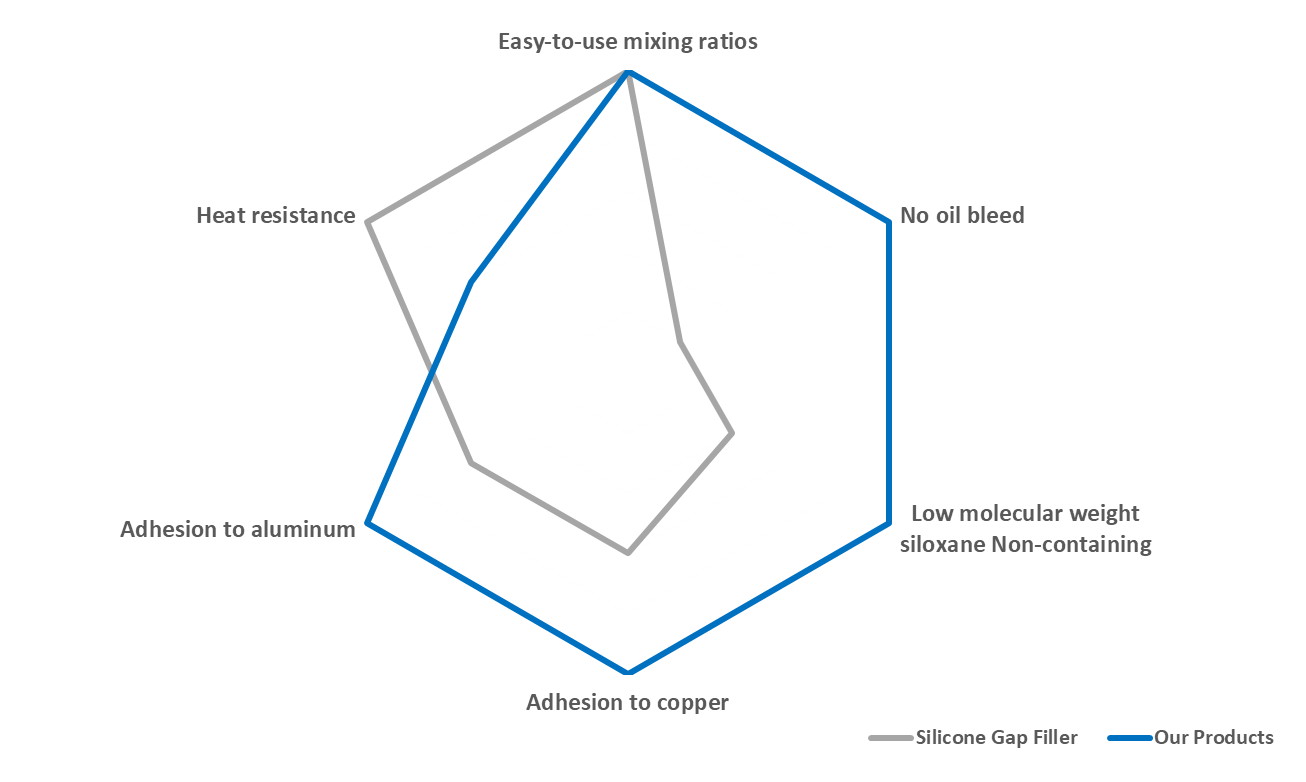

Differences between our developed products and silicone binders

- No oil bleed, and the same characteristics can be maintained for a long period of time.

- Non-use of silicone components. Low risk of contact failure due to non-inclusion of low molecular weight siloxane.

- Good adhesion to copper and aluminum. Therefore, high heat removal effect is realized with low contact heat resistance.

Scheduled to be completed in April 2023!

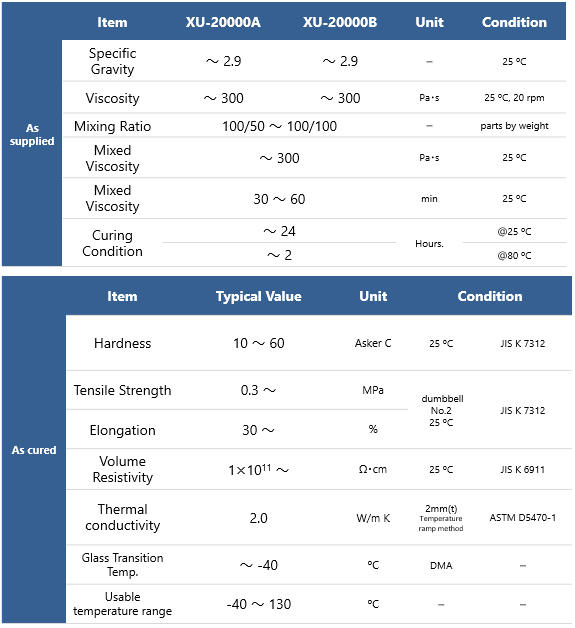

Developed products PEL Urethane®XU-20000A/B

Strong Point

- Can be stored at room temperature

- The pre-cured state is a moderately viscous substance (grease-like), so it does not drip and is easy to work with. It also reduces the load on components during mounting

- Flexible after curing, high thermal conductivity

- No pump-out and dry-out

- Low temperature curing is possible. Immediate curing is also possible by heating

- No silicone resin is used, reducing the risk of electronic contact failure

Use

・Uneven parts and parts requiring stress relief

・Locations where the distance between the heating element and the heat-dissipating element is large

・Heat dissipation near electronic contacts

・Parts that cannot be heat cured

Specification

From the Developer to You

Nice to meet you! Thank you for visiting our blog.

I am Sone, a developer.

The evolution of miniaturization of components has been remarkable in recent years, and at the same time, thermal countermeasures have become a major issue.

In some cases, heat countermeasures are taken by increasing the heat resistance of components, but there are also many cases where a heat exhaust system using a heat dissipation gap filler is also considered at the same time. Inquiries about heat dissipation gap fillers are increasing year by year, and we are aware that there are many customers who require high thermal conductivity and fluidity of the liquid before curing.

In fact, we have been making many prototypes for the best products based on the feedback from our customers.

We would very much like to reflect the voices of those who are looking for heat dissipation gap filler and those who have issues, so please fill out the questionnaire. If you have any questions about our products, meetings, or other inquiries, please feel free to contact us.

We would like to hear from you.

We would like to make use of your opinions in the development of the XU-20000A/B,

and would appreciate your cooperation in filling out the survey.