Excellent transparency. Light conductive. Bendable. Non-yellowing.

| Product Category | by Use | by Function | |||

|---|---|---|---|---|---|

| Product Category |

|

by Use |

|

by Function |

|

Excellent transparency. Light conductive. Bendable. Non-yellowing.

| Product Category | by Use | by Function | |||

|---|---|---|---|---|---|

| Product Category |

|

by Use |

|

by Function |

|

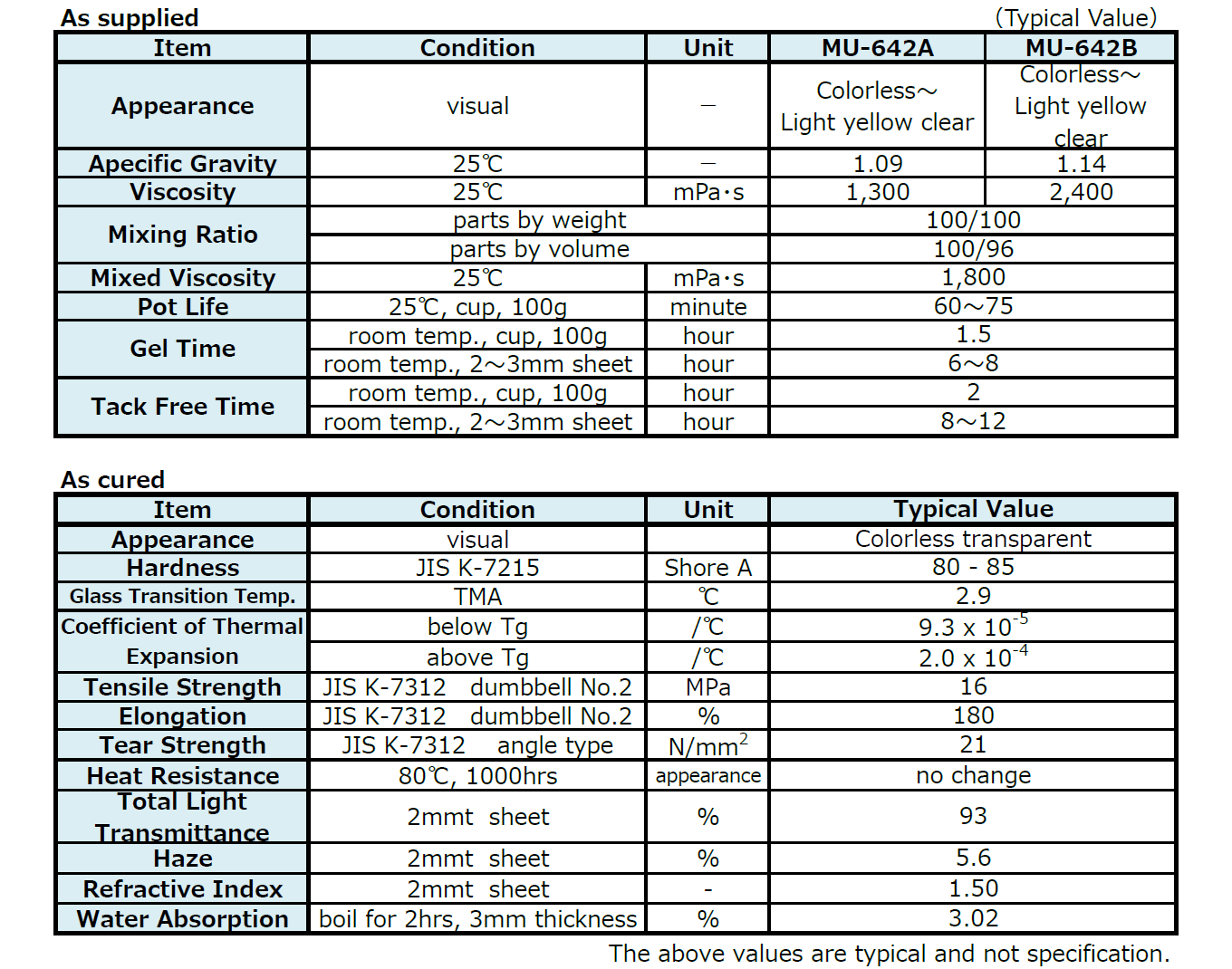

MU-642A : 18kg

MU-642B : 18kg

Please feel free to contact us You can request Sample, SDS, Composition Table and other Data Sheets etc.