Resins for model making by vacuum casting. Soft rubber type (variable hardness).

| Product Category | by Use | by Function | |||

|---|---|---|---|---|---|

| Product Category |

|

by Use |

|

by Function |

|

Resins for model making by vacuum casting. Soft rubber type (variable hardness).

| Product Category | by Use | by Function | |||

|---|---|---|---|---|---|

| Product Category |

|

by Use |

|

by Function |

|

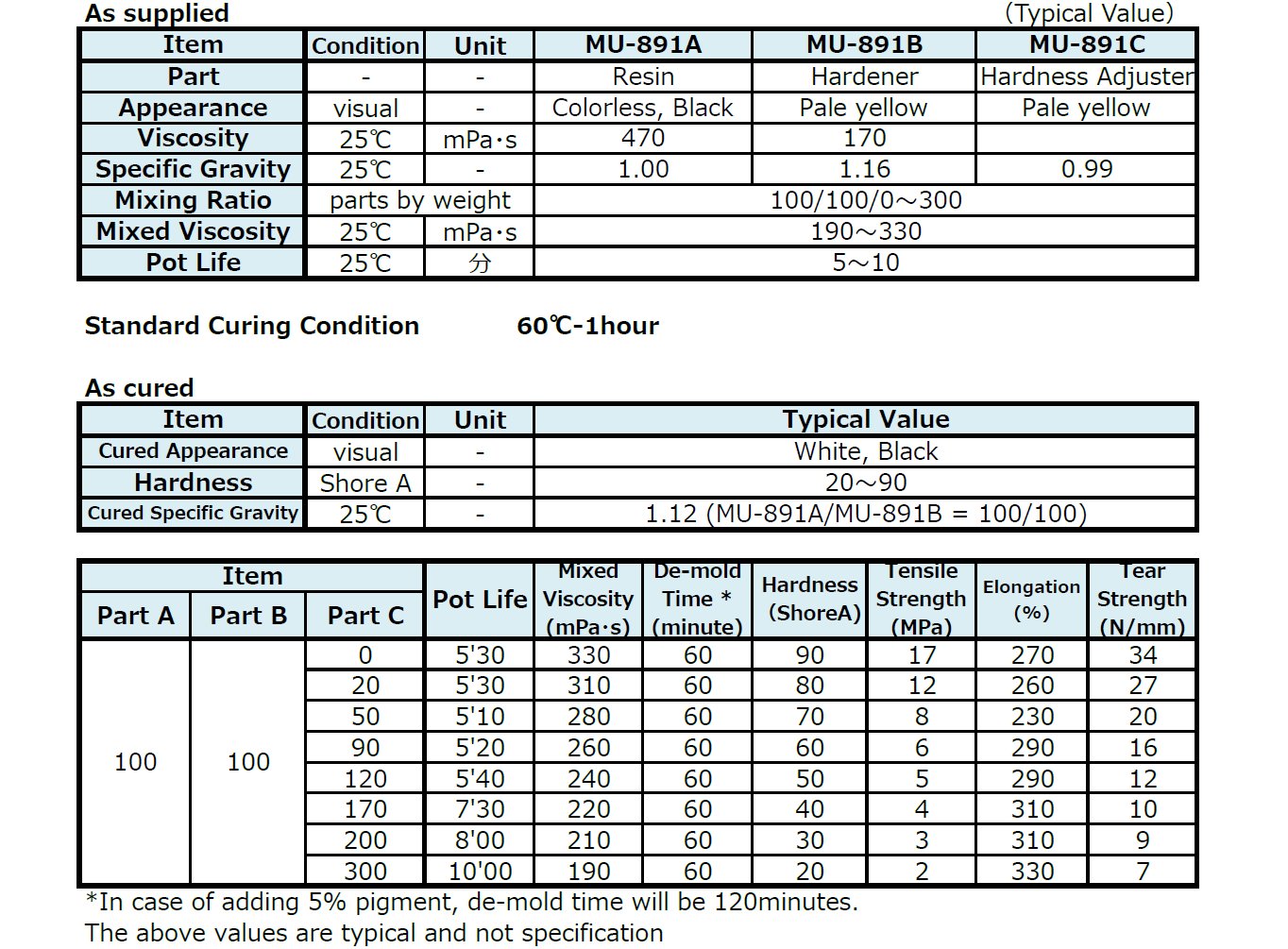

MU-891A : 1Kg

MU-891B : 1Kg

MU-891C : 1Kg

Please feel free to contact us You can request Sample, SDS, Composition Table and other Data Sheets etc.