1.Resin Summary

Epoxy resins are a type of engineering plastic.

Plastic materials are classified into two types: thermoplastic resins, which soften when heated and harden when cooled, and thermosetting resins, which cure through a chemical reaction when heated.

Epoxy resins are classified as thermosetting resins.

2.What is epoxy resin?

The structure of cured epoxy resins has a three-dimensional network structure and is known to be harder and chemically more stable than the cured products of other common organic resins.

Since the world’s first “Bisphenol A type epoxy resin” was developed, it has been used in a wide range of applications from daily necessities to advanced materials.

Currently, its use is expanding mainly in the electrical, civil engineering and beverage cans,

In particular, it is used in almost all electrical appliances, including smartphones.

What are the features of epoxy resin?

●Heat resistance : It can resist high temperatures because of its molecular structure, which is a three-dimensional network.

●Adhesion : It has high adhesive properties and can bond various materials such as metal and concrete.

●Mechanical strength : It has high toughness and can be used in carbon fiber reinforced plastic (CFRP) applications where high strength is required.

●Electrical insulation : It can be used as an insulator because it does not conduct electricity.

●Dimensional stability : It has less shrinkage during curing and can be used for size-accurate parts.

●Chemical resistance / Water resistance / Waterproof: It does not dissolve in any solvent because its molecular structure forms a three-dimensional network.Therefore, it can be used for beverage cans & ships painting etc.

Cured epoxy resins have a good balance of heat resistance, adhesion, and electrical insulation, as well as selectable properties such as transparency and flexibility.

Therefore, they are widely used not only as advanced materials but also in various applications such as adhesives, civil engineering, paints, composite materials, and hobby.

3.Reaction Mechanism

Epoxy resins do not react alone.

Therefore, it must be used with a hardener or catalyst.

The reaction of epoxy resins proceeds by ring-opening of the oxirane ring, so no byproducts are released after the reaction.

The molecular structure produced by the reaction forms a three-dimensional network structure.

Therefore, insoluble, non-melting and high heat resistance cured products can be obtained.

Major curing agents are amine compounds, acid anhydrides, basic catalysts and Lewis acid catalysts.

Curing reaction systems for epoxy resins are as follows.

①Addition reaction of epoxy resin and amine compound

Reaction with amine compounds is the most popular curing reaction for epoxy resins.

Generally, it reacts with epoxy resins under room temperature, yielding a reaction product that is tough and has excellent adhesive properties.

There are several types of polyamines, including aliphatic polyamines, alicyclic polyamines, aromatic polyamines, and modified polyamidoamines, which are used depending on the application and curing conditions.

②Copolymerization of epoxy resin and acid anhydride

Reaction with acid anhydride requires heat curing (100°C or higher), but it has low mixing viscosity and a long pot life, making it excellent for handling.

Reaction product has high Tg and excellent electrical insulation, mechanical properties, and heat resistance.

Because it is safer than amine compounds, it is the most generally used curing agent in the field of electrical and electronic insulating materials.

③Self-polymerization of epoxy resins with basic or acidic catalysts

Epoxy resins are substances that can be cured by anionic, cationic, or coordination polymerization.

Among these, anionic polymerization with imidazoles and the like is generally used.

Unlike other curing agents, it can be cured by adding a small amount to epoxy resin.

It cures in a short time under curing temperature conditions of 120°C to 150°C and produces a cured product with a high Tg.

4.Use

Epoxy resins are used in a wide variety of applications because of their various features and advantages.

Typical applications include the following.

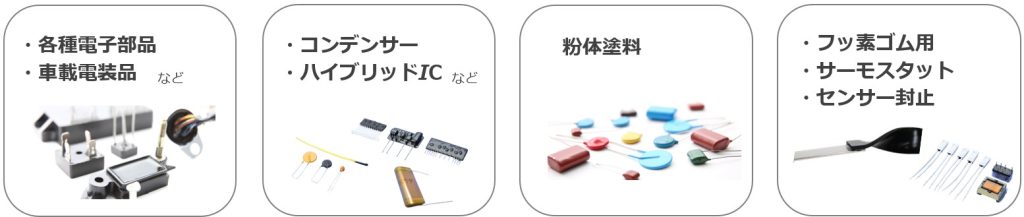

①Electronic components

Encapsulating materials used for electronic components require excellent electrical insulation, mechanical properties, thermal properties, etc.

And, since there are various types of electronic components, such as passive components, LEDs, sensors, and automotive electrical components, they must also have molding flexibility.

These requirements can be satisfied by using epoxy resins as encapsulants.

②Semiconductors

Semiconductor devices have a structure in which the chip is bonded to a substrate or lead frame by bonding wires.

Therefore, encapsulation by resin is used to prevent damage to semiconductor chips and bonding wires and to improve device reliability.

Encapsulating resins need to have various performances such as adhesion to semiconductor chips and substrates, heat resistance, insulation, low thermal expansion coefficient, and mechanical strength.

Among encapsulating resins, epoxy resin encapsulating materials are widely used as semiconductor encapsulating resins because of their high heat resistance and mechanical strength.

③Coatings

Epoxy resins are also used as coatings due to their excellent adhesion, water resistance, and insulation properties.

Coatings are broadly classified into liquid-type and powder-type, and there are various coating methods depending on the intended use.

We mainly supply coatings for electronic components and copper used in “bus bar”.

④Adhesives

Epoxy resins have excellent adhesion and bonding strength.

Therefore, it is used as an adhesive in a wide range of industrial and consumer applications.

Since adhesive strength depends not only on the type of epoxy resin, but also on the curing agent, there is an optimal combination for materials to be bonded.

We can offer both one- and two-component types.